Videos

Keep the Job Moving when a connection hole is undersized

VersaDrive reamers are the perfect hole alignment and enlarging tool for metalworkers & steel erectors for keeping the job moving when a hole is misaligned or the incorrect size for the fixing.

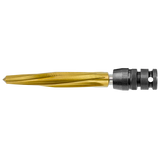

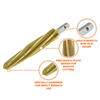

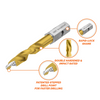

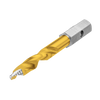

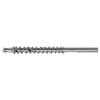

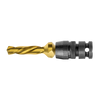

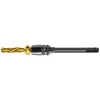

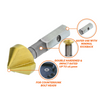

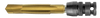

Featuring a specially designed 6 flute cutting geometry and Titanium coating, VersaDrive Reamers are fully Impact rated and perform fastest when used with an Impact Wrench providing ultimate cutting performance with virtually no powertool kickback.

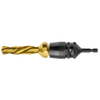

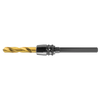

VersaDrive Reamers have a patented nonslip, Hex shank suitable for use in any standard 1/2” drill chuck for Pistol Drills or used with a VersaDrive Rapid Lock adapter for use in a wide range of powertools such as Magnetic Drills.

For larger diameter reaming see VersaDrive MAX Reamers

Product Benefits

- Precision 6-flute design for smooth cutting

- Edge cutting design for hole enlargement, giving much better results that a drill bit

- Industrial grade Titanium Nitride coating reduces heat buildup and burn-out

- Use on Impact to prevent dangerous kickback caused by handheld rotary tools

- Heavy-duty hex shank design for secure non-slip operation

- Quality results on stainless steels and Inox - rotary application recommended

- VersaDrive patented shank and modular adapters provide unbeatable jobsite flexibility

- Impact-rated due to dual hardening process - allows up to 15X faster speed than traditional methods

Quick Guide

- For fastest performance use on Impact Wrenches & Impact Drivers

- Not recommended for Impact use with flame, plasma or laser cut holes

- For flame, plasma or laser cut holes use with a Magnet Drill

- Reamer should be rotating before starting the cut & steady feed pressure used throughout

- For materials thicker than 3/4" use of VersaDrive MAX Reamers is recommended