Videos

15X Faster than Hand Tapping

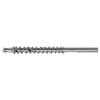

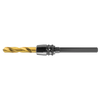

For Tapping thick materials or in applications requiring extra length to access the hole

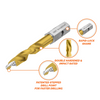

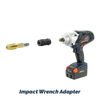

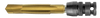

VersaDrive® ImpactaTaps are the first range of taps that are suitable to be driven by impact wrenches and impact drivers, providing at least 15x faster performance than tapping by hand.

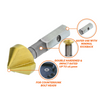

With a specially designed twin-lead, cutting geometry - the dual hardening process with Titanium coating provides a fantastic solution for tapping holes in steel.

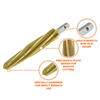

VersaDrive® ImpactaTaps have a patented non-slip, Hex shank suitable for use in any standard 1/2" drill chuck for cordless or pistol drills (up to M10) or used with a VersaDrive® Rapid Lock adapter for use in a wide range of powertools such as Magnetic Drills. They can even be used by hand in a socket wrench.

Product Benefits

- Impact Chipbreaker action for effective swarf evacuation

- Unique twin-point cutting geometry with ground flutes

- Create internal threaded holes with speed and precision

- Quickly clean out and repair damaged or fouled internal threads

- Industrial grade Titanium Nitride coating reduces heat buildup and burn-out

- Use on Impact to prevent dangerous kickback caused by handheld rotary tools

- Heavy-duty hex shank design for secure non-slip operation

- Impact-rated due to dual hardening process - allows up to 15X faster speed than traditional methods

Quick Guide

- For fastest performance use on impact wrenches & impact drivers

- Check the minimum torque requirement

- Tapping Stainless Steel requires higher impact torque

- Use appropriate lubrication and correct RPM to achieve long tool life