News — magnet drill

CarbideMax TCT broach cutters by HMT cut up to 64% faster and last up to 10 times longer than HSS cutters. Over their lifespan this more than halves...

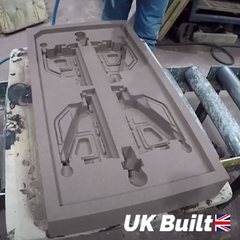

Manufacturing the 'Made in Britain' VersaDrive V35 compact magnet drill occurs in stages. To begin, the machine body must be cast from raw aluminium at a UK based foundry. More...

Manufacturing the most flexible compact magnet drill on the market so it is not only lightweight but capable of withstanding daily industrial use requires expert craftsmanship and experience. This is...

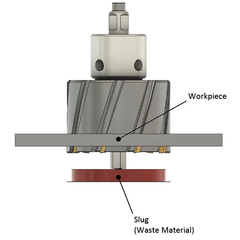

Using standard broaching practices, a disc of waste material known as a ‘Slug’ is produced when drilling metal. Typically, this falls harmlessly from the work area to the floor below...