Wedge Group:

A Case Study with Wessex Galvanisers

Cutting Costs & Time with VersaDrive® TurboTip Drill Bits

Industry: Metal Finishing & Galvanizing

Location: Eastleigh, UK

Products Used:

VersaDrive® TurboTip Impact Drill Bits (8mm & 10mm)

Tools: VersaDrive® Impact Wrench

The Challenge: Drilling Holes Was Slow, Costly, and Unsafe

At Wessex Galvanizers, part of Wedge Group Galvanizing Ltd, drilling holes in steel plate up to 10mm thick was once one of the toughest, most time-consuming parts of their process.

Using standard cordless drills and conventional rotary drill bits, their team faced three major issues:

-

High cost per hole:

Standard 10mm “high-quality” bits delivered only 2–3 holes each—costing a staggering £2.19 per hole. -

Slow, hard work:

Forcing a rotary drill bit through thick steel was exhausting and time-intensive. -

Safety risks:

Snatching and kickback experienced when drill bits snagged often caused painful wrist impacts and could damage batteries, creating constant health and safety concerns.

In short—drilling was inefficient, expensive, and unsafe.

The Solution: Switching to VersaDrive® TurboTip Impact Drill Bits

In May 2025, Wedge Group member Wessex Galvanizers upgraded to VersaDrive® TurboTip Impact Drill Bits, used with impact wrenches instead of rotary drills.

The difference was immediate.

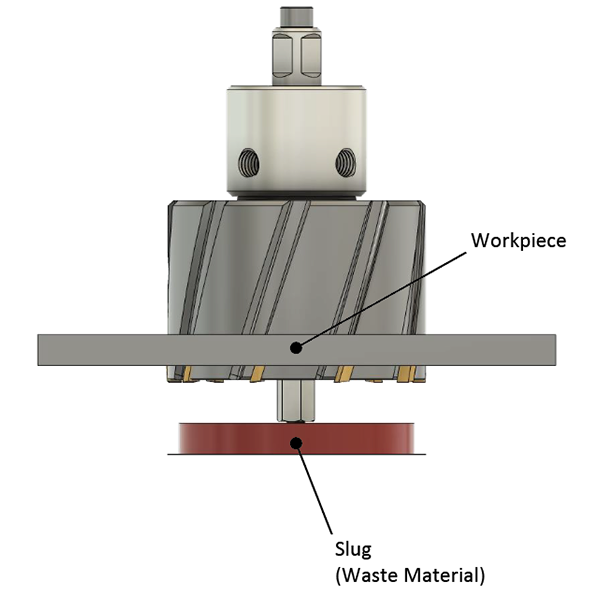

VersaDrive® TurboTips harnessed the power of the impact wrench to cut faster, cleaner holes—with less effort and no kickback.

Their team now uses the 8mm and 10mm TurboTip bits across a range of steel thicknesses up to 10mm with an impact wrench, and mag drills for heavier work.

The Results: Massive Savings in Time and Cost

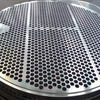

Since adopting VersaDrive®, Wessex Galvanizers has drilled over 5,100 holes—and the results speak for themselves:

| Metric | Before VersaDrive® | After VersaDrive® |

|---|---|---|

| Average holes per bit | 2–3 holes | 72 holes |

| Cost per hole (10mm) | £2.13 | £0.38 |

| Drilling speed | Slow, high effort | Less than half the time |

| Safety | Frequent snatch/kickback | Low vibration, no kickback |

In just a few months, Wessex Galvanizers have spent a fraction of what they once did on drill bits—and saving countless man-hours in the process.

“Since we’ve used VersaDrive®, the guys can’t see how they can use an ordinary drill now. They think it’s Stone Age!”

— Matt Bartrop, Wessex Galvanizers

The Outcome: Faster. Safer. Smarter.

- Cost savings: £1.75 saved per hole compared to standard bits, without even factoring the cost of the time saved

- Efficiency: Over 2x faster drilling speed

- Safety: Reduced vibration, zero kickback

- Durability: 24x more holes per bit

These measurable improvements have delivered thousands of pounds in savings and significantly improved worker safety and productivity.

The Takeaway

Wessex Galvanizers’ success highlights how VersaDrive® TurboTips redefine what’s possible in on-site metalworking — cutting faster, costing less, and keeping teams safer.

If your crew is still struggling with standard drill bits, book a VersaDrive® demo or speak to our team today and see how VersaDrive® could improve your processes.

sales@holemaker-technology.com

03330 110 382