Videos

Simply the best long-life twist drill bits for Metal

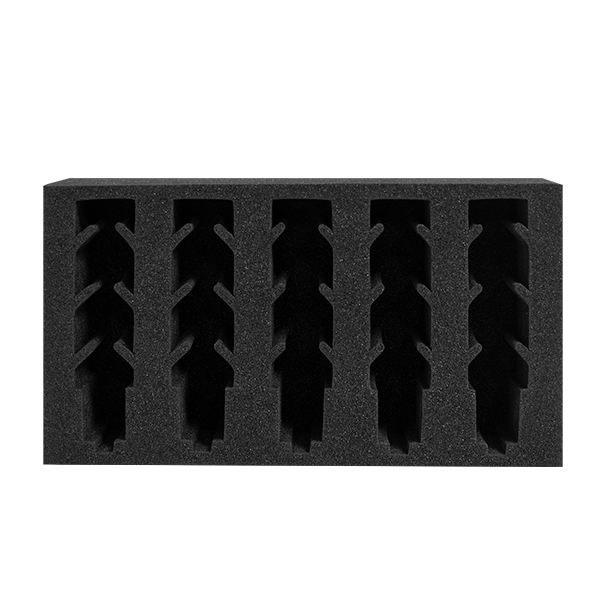

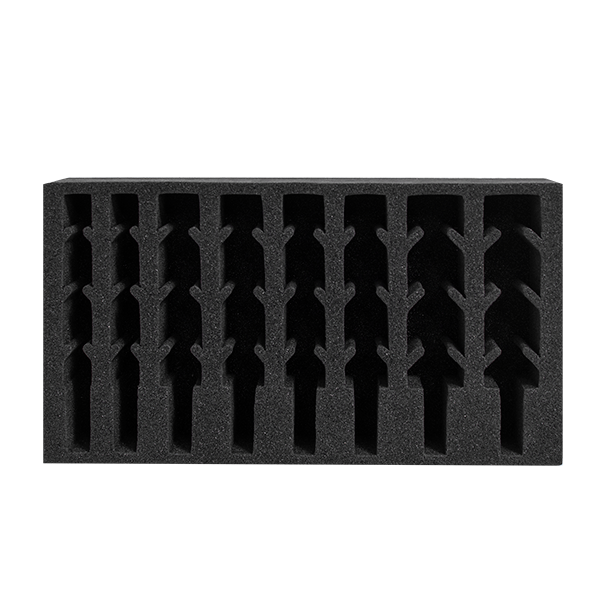

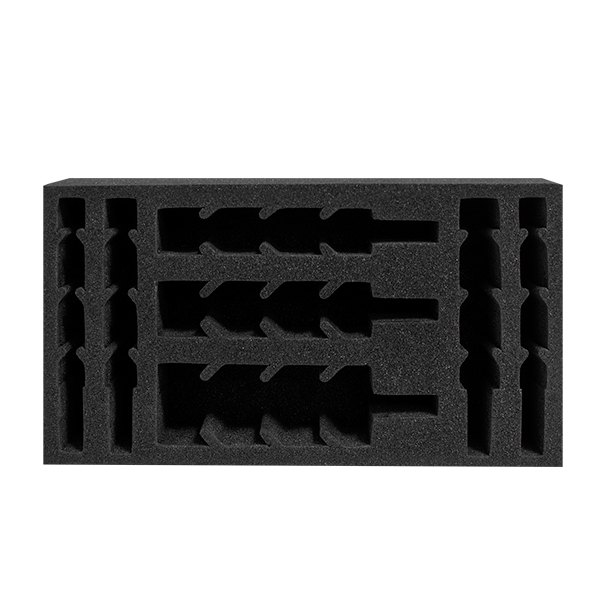

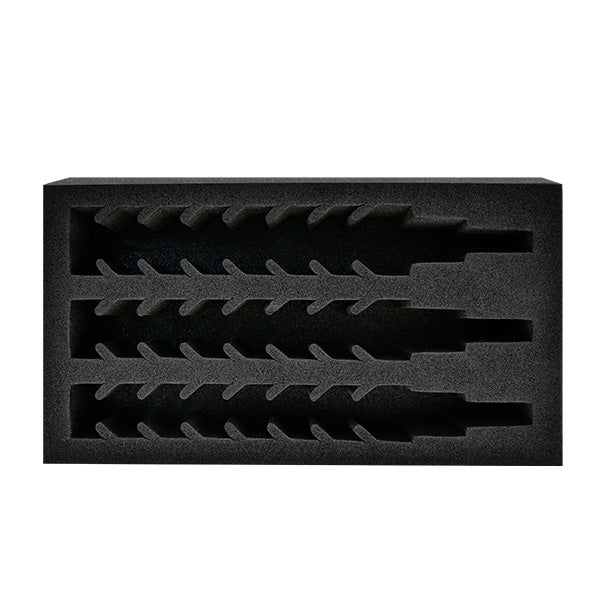

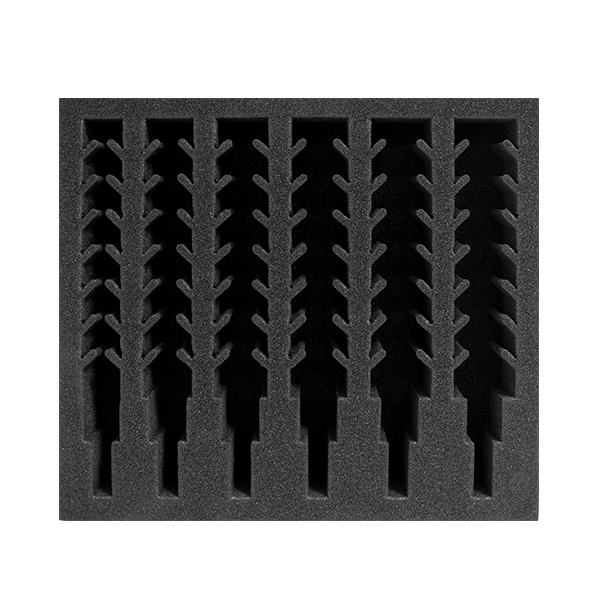

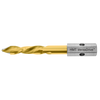

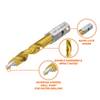

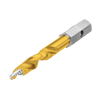

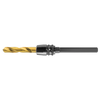

VersaDrive® Cobalt Drills are a premium grade 8% Cobalt drill bit with fully ground flutes, 135° Split point and Titanium coating for faster drilling & reduced wear.

Suitable for heavy fabrication use, this Cobalt drill bit can also be used to drill stainless steel, mild steel, cast iron and a wide range of other structural materials.

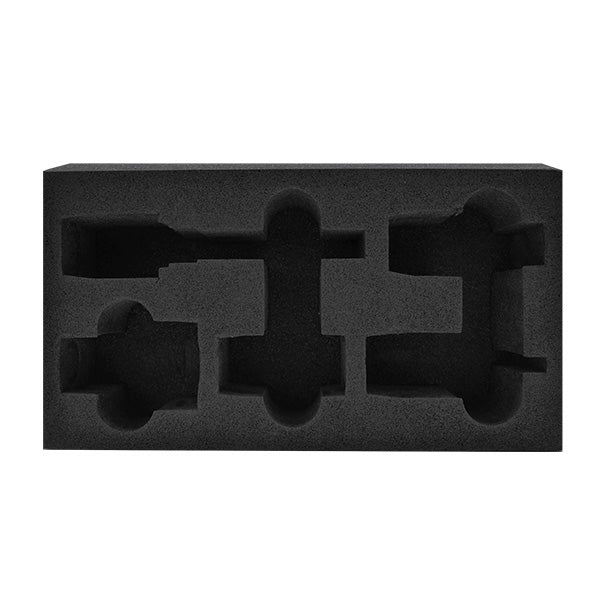

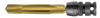

VersaDrive® Drill Bits have a patented non-slip, Hex shank suitable for use in any standard 1/2" drill chuck for cordless or pistol drills or used with a VersaDrive® Rapid Lock adapter for use in a wide range of power tools such as Magnetic Drills.

Product Benefits

- Precision ground flute design provide easy chip clearance

- 8% Cobalt tool steel for long life & endurance with 135º split point for easy starting & high accuracy

- Industrial grade Titanium Nitride coating reduces heat buildup and burn-out

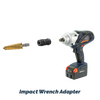

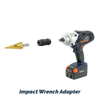

- Use on Impact to prevent dangerous kickback caused by handheld rotary tools

- Heavy-duty hex shank design for secure non-slip operation

- Quality results on stainless steels and Inox - rotary application recommended

- VersaDrive patented shank and modular adapters provide unbeatable jobsite flexibility

- Impact-rated due to dual hardening process - allows up to 15X faster speed than traditional methods

Quick Guide

- Optimum life and performance when used with rotary pistol drills

- Up to 10.5mm can be used on impact wrench & impact drivers for fast cutting performance

- Suitable for use on stainless steel and harder materials if used at low RPM in Rotary tools

- Use appropriate lubrication and correct RPM to achieve long tool life