Videos

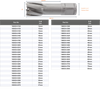

CarbideMax Ultra cutters are specifically designed for long-life performance in the toughest broaching jobs on the planet, including use on wear plates such as Hardox®, RAEX® and CREUSABRO®.

Product Benefits

- Individually brazed, highest quality carbide cutting teeth

- ULTRA coated for optimum performance & lifespan

- Elaborate cutting geometry for faster, quieter drilling

- Chatter free performance when used correctly

- Up to 55mm depth of cut

- Standard 19.05mm Weldon shank

- Use with high torque/slow speed, geared magnet drills