Videos

,

,

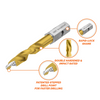

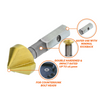

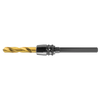

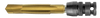

Drill & Tap in one easy operation

The first impact rated Farriers Combi-Drill-Tap rated for use with Impact Drivers & Impact wrenches. Can also be used in a standard cordless drill for non-impact use.

- Standard Size for Horseshoe Studs

- 15 times faster than hand tapping - Drill then Tap stud holes effortlessly, in seconds

- Specially Hardened for use with an Impact Driver

- Hi-tech premium TiN coating for smooth cutting and low heat buildup

- Long tool life - Typical life 250 Horseshoes tapped

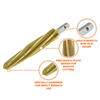

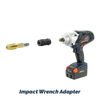

- When using with an impact wrench or impact driver the appropriate adapter is required

- For best results, use Speedlube cutting spray for lubrication