Videos

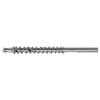

The VersaDrive® DrillSink - Combination Drill ensures smooth countersinking and perfect accuracy every time

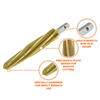

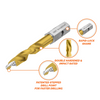

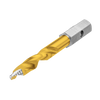

The VersaDrive Drillsink is an innovative combined drilling & countersinking tool to save metalworkers time & increase hole accuracy by drilling & then countersinking fixing holes in one operation.

This combination tool provides perfect countersinking accuracy every time by locating the drilled hole in perfect alignment to the countersink. This helps prevent tool chatter and blunting commonly found with standard countersinks.

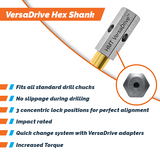

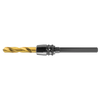

VersaDrive® DrillSinks have a patented non-slip, Hex shank suitable for use in any standard 1/2" drill chuck for cordless or pistol drills or used with a VersaDrive Rapid Lock adapter for use in a wide range of powertools such as Magnetic Drills.

Product Benefits

- Drill & countersink in one easy operation to speed up metalworking

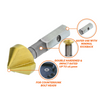

- Ground flutes for high accuracy & long life

- Integrated pilot drill prevents the chattering of standard countersinks

- Perfect concentricity for accurate countersinking

- Industrial grade Titanium Nitride coating reduces heat buildup and burn-out

- Heavy-duty hex shank design for secure non-slip operation

- Quality results on stainless steels and Inox - rotary application recommended

- VersaDrive patented shank and modular adapters provide unbeatable jobsite flexibility

Quick Guide

- Optimum life and performance when used with rotary pistol drills and magnet drills

- Can be used with impact tools up to 16.5mm

- Suitable for use on harder materials such as stainless steel when used at reduced RPM

- Use appropriate lubrication and correct RPM to achieve long tool life