News — Broaching

The use of Hot Metal Rivets as a means of connection in Industrial Steelworks dates back to the early-mid 1800s when they were used in the construction of everything from...

CarbideMax TCT broach cutters by HMT cut up to 64% faster and last up to 10 times longer than HSS cutters. Over their lifespan this more than halves...

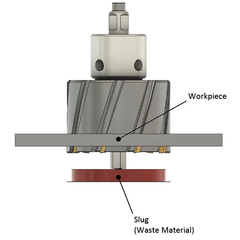

Using standard broaching practices, a disc of waste material known as a ‘Slug’ is produced when drilling metal. Typically, this falls harmlessly from the work area to the floor below...

Holemaker Technology chosen once again to support construction at British Antarctic Survey’s Rothera Research station.

A test rig for a client needing to broach through 150mm+ of stacked steel plate, in one operation. This was successfully achieved utilising CarbideMax 200mm depth of cut TCT Broach...