Videos

MODIFY OR ENLARGE HOLES

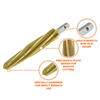

The ImpactaMag™ HSS reamer is a unique double-use reamer for enlarging and aligning holes in metals and hard materials.

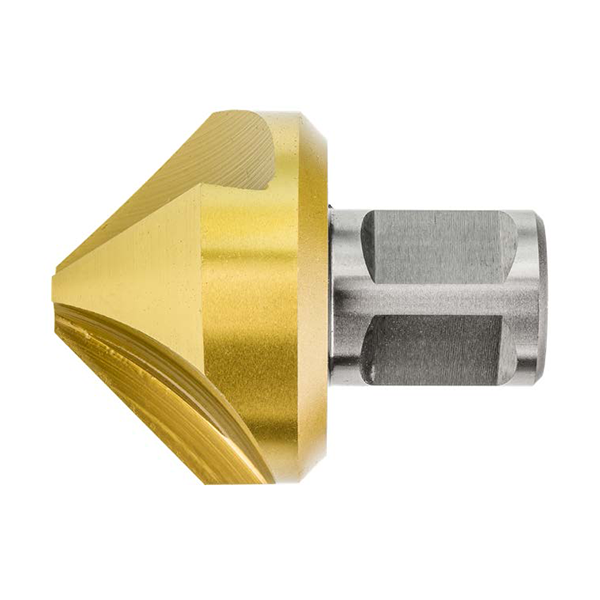

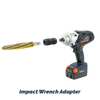

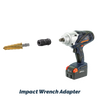

Specially designed cutting geometry allows the tool to be used in an Impact wrench or a Magnet drill. When used in an Impact wrench it is secured into a special adapter meaning the tool is easier to control, apply correct feed rate, and withdraw from the finished hole, enhancing tool life. This reamer will also fit into a standard Weldon magnet drill arbor.

Product Benefits

- Ideal for steel erection & bridge work

- Ideal for modifying & enlarging holes

- Secured directly to the Impact Wrench

- Can be used with any standard Magnet Drill

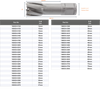

- Available in intermediate sizes

- Unique 6 flute design for faster, smoother cut

- Prepare holes ready for installation of TCB & friction grip bolts