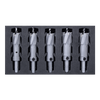

Videos

10X LONGER LIFE THAN STANDARD HOLESAWS

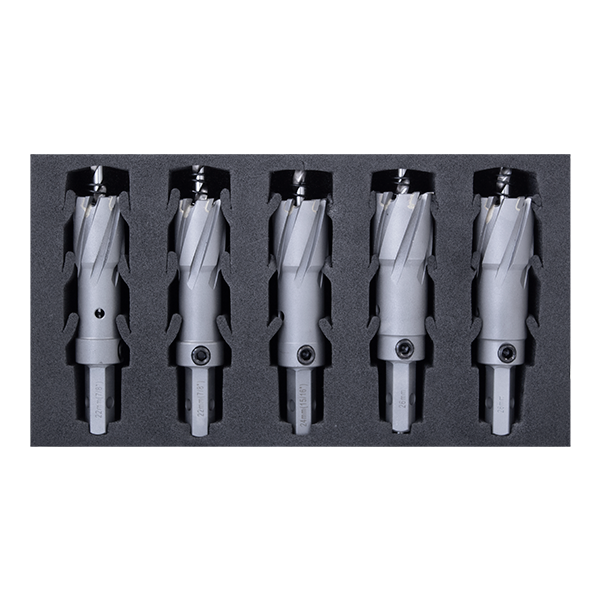

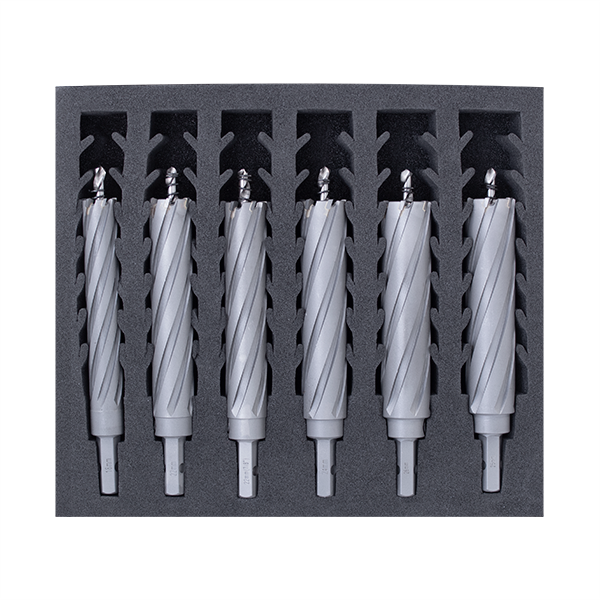

VersaDrive TCT Holecutters are a high performance solution for cutting larger diameter holes quickly and effectively. Premium grade Tungsten carbide teeth provide ultimate cutting performance in a wide range of Structural steels including Stainless Steel and Cast Iron.

The go-to solution for fabricators and steel erectors needing to drill through heavy steel in locations and on projects where a rotary drill is more convenient and safer than a Magnetic drill.

VersaDrive TCT Holecutters have a patented non-slip, Hex shank suitable for use in any standard 1/2" drill chuck for cordless or pistol drills or used with a VersaDrive Rapid Lock adapter for use in a wide range of powertools such as Magnetic Drills.

Product Benefits

- Massive 70mm reach with 55mm depth of cut

- Perfect for drilling heavy steel in remote locations

- Premium quality Tungsten Carbide teeth

- Use with Magnet Drill adapter

- Use in standard 1/2" drill chuck

- One piece design includes arbor & (replaceable) pilot drill

- Combine with MultiSink to broach & countersink in 1 pass

Quick Guide

- Optimum life and performance when used with rotary pistol drills

- Good results can be achieved with SDS Drills when used in Rotary Only mode

- Replace supplied pilot drill with 101030P-0003 ejector pin for use with a Magnet Drill or MultiSink

- Suitable for use on Stainless Steel

- Use appropriate lubrication and correct RPM to achieve long tool life