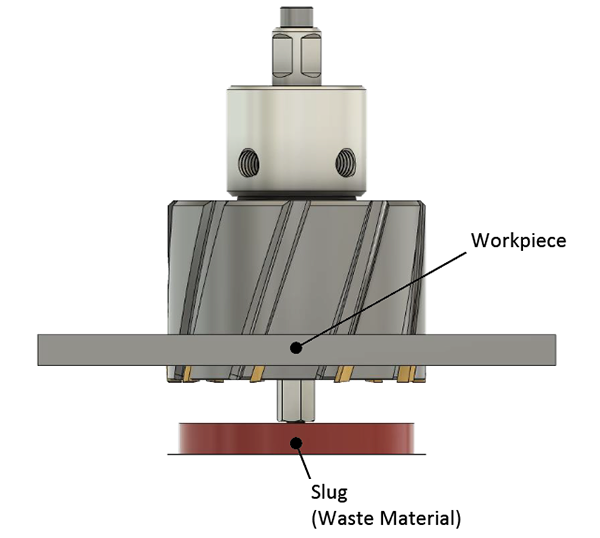

Using standard broaching practices, a disc of waste material known as a ‘Slug’ is produced when drilling metal.

Typically, this falls harmlessly from the work area to the floor below and doesn’t present an issue.

However, in several specialist or hazardous applications such as working at height or drilling above delicate machinery, the inability to retain a slug or prevent it from falling can pose a significant challenge or danger.

Where this is the case a job is often delayed whilst awkward solutions are implemented or put on hold indefinitely if no workaround can be found.

To overcome these costly and time-consuming stoppages, Holemaker Technology has developed a unique Slug Retention System that is guaranteed to keep control of slugs and prevent them from injuring anyone or damaging essential machinery.

Using a customised pilot pin and pilot hole this HMT exclusive process offers a new, innovative and bespoke solution that can be customised to the exact needs of the job.

No matter what your application you can have confidence that it has been developed with your project in mind.

For more information or a custom quote please contact sales@holemaker-technology.com or call 03330 110 382 to discuss your project.